WASHINGTON D.C.—The House Transportation & Infrastructure Subcommittee heard testimony from Michael Whitaker, Administrator of the Federal Aviation Administration (FAA), on Tuesday, September 24, focused on its oversight of Boeing’s corrective action plan following Alaska Airlines Flight 1282 incident.

Whitaker briefed the committee back in June on Boeing’s manufacturing and production process and appeared before it again Tuesday with an update. Whitaker mandated Boeing to implement a comprehensive plan back in February which, he said, does not mark the end of the FAA’s oversight of the aviation company.

“There must be a profound shift in the company’s safety culture to holistically address its quality assurance and production challenges,” said Whitaker.

The FAAhas increased its safety inspectors at both Boeing production and Spirit AeroSystems’ facilities since January 5 and plans to continue engaging with company employees, performing additional inspections at critical points in the production process, and increasing auditing of build processes going forward.

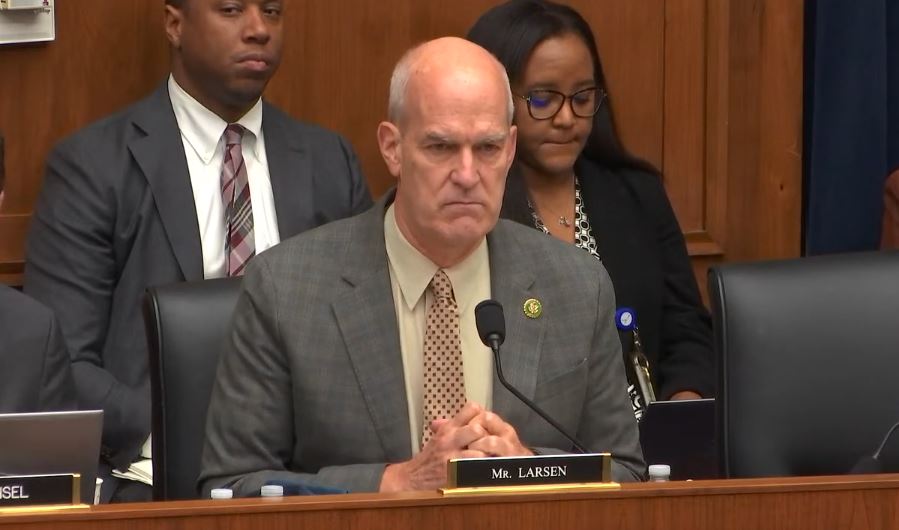

As ranking member Representative Rick Larsen (WA-02) put it, Tuesday’s hearing was really “two hearings in one;” the first, motivated by the aftermath of the Alaska Airlines Flight 1282 door plug accident, examining Boeing’s safety culture problems, the FAA’s subsequent investigation, and Boeing’s comprehensive plan to investigate these issues; the second evaluating the FAA’s general oversight of U.S. Aviation manufacturing to prevent accidents like this ever happening again.

“Just as we did five years ago this committee must remain vigilant in its oversight and authorization roles and hold those responsible accountable wherever the FAA and NTSB investigations lead,” said Rep. Larsen Tuesday calling upon the Boeing company to revamp its safety culture, particularly as it relates to its greatest asset – its workers. “It’s not enough to build airplanes in the U.S. We must build safe airplanes in the U.S. How congress and the FAA respond to this event will have lasting impacts.”

Following that incident the FAA grounded the 737 MAX 9 fleet for nearly 20 days and the NTSB initiated an investigation. The FAA also launched a concurrent, but separate, investigation and called for an audit for the 737 production line and its suppliers. The FAA took the following oversite actions:

- Capping production of new Boeing 737 MAX to 38 airplanes per month to achieve system stability and compliance with required quality control procedures.

- Launching an investigation scrutinizing Boeing’s compliance with manufacturing requirements.

- Increasing oversight of the production of new airplanes with more FAA safety inspectors on-site at all Boeing manufacturing facilities.

- Increasing data monitoring to identify significant safety issues.

- Commissioning an independent analysis of potential safety-focused reforms around quality control and delegation.

The door plug incident was far from the only quality concern issues raised concerning Boeing’s production line recently. In May of 2021, Rep. Larsen and then Chair Peter DeFazio (D-OR) wrote to the Department of Transportation, the FAA, and Boeing about concerns about no less than 9 reports of quality control issues at Boeing productions facilities. Since then, there has been dozens more reports leading to emergency fixes to its fleet and halts in production.

At Tuesday’s meeting Representative Steve Cohen (TN-09) said that Boeing is one of “America’s premier companies” but “needs to get its act together” for America’s best interest.

During his opening remark, Garret Graves (R-LA), Acting Chair of the House Transportation subcommittee, commended the FAA for its immediate action in expanding oversight of Boeing’s production line following the Alaska Airlines Flight 1282 door plug accident while also demanding the company implement a comprehensive action plan to address production deficiencies.

The FAA’s oversight of Boeing comes at a time when the agency is tasked with a historic 1,000-page reauthorization bill that governs aviation over the next five years and requires specific deadlines and urgent actions to improve aviation efficiency and safety.

“It’s no secret that the United States has the gold standard of aviation,” said Chairman Graves. “Some of the incidents that have happened in recent months and years have certainly called that in to question and caused us to ensure that we’re staying on top of that, to ensure that we’re working to maintain that standard, to improve that standard.”

The Alaska Airlines Flight 1282 door plug incident represents one of the most visible elements of an aviation system that’s been strained and sometimes passed the breaking point, Chairman Graves added.

Whitaker’s testimony shared that the FAA is currently reevaluating its current safety oversight models to address changing technologies and business models while also revamping its agency-wide safety management program. As part of this strategy the FAA plans to reconstitute its executive committee which oversees regulatory oversight and safety management programs and continually monitors the system as a whole—a program that will be chaired by Whitaker himself.

The FAA is also examining opportunities to better leverage its vast data resources to become more “predictive” in identifying risks across the aviation system.

“The safety and integrity of our air transportation system relies heavily on the operators in that system having a strong safety culture,” said Whitaker. “A culture where safety is first, not in name only but in how that operation is run. Safety must come before financial incentives, production targets, or operational goals. Employees must have the ability, in fact encouraged, to speak up and come forward with safety concerns without fear of reprisal.”

On March 9, Boeing whistleblower John Mitchell Barnett was found dead in his truck outside of a hotel in Charleston, South Carolina. Barnett, a former quality control engineer at Boeing, claimed the company retaliated against him and was continually harassing and spying on him after he rose to whistleblower status. Barret alleged that Boeing rushed its 787 Dreamliner to completion and was critical of the return of the 737 MAX 9 back to flight.

Congress has expanded Safety Management Specialist (SMS) requirements to most major operators in the air transportation system including major airlines, operators, airports, and aircraft manufacturers.

Whitaker noted Tuesday that it is currently safe to fly on a Boeing 737 as the FAA conducts a thorough inspection, in addition to Boeing’s own, of every certified aircraft.

He continued that implementing a “safety culture” is a long term goal and doesn’t expect Boeing to make any major shifts in the coming months.

Still, after Whitaker’s testimony, ranking member Rep. Larsen asked him about Boeing’s progress on it six key performance indicators:

- Employee proficiency: The percentage of employees who are proficient in core skills

- Notice of escape (NoE) rework hours: The time spent on rework in the final assembly facilities due to non-conforming work

- Supplier shortages: The number of shortages per day from Boeing Fabrication and external suppliers

- Rework hours per airplane: The total time spent on rework per airplane in the final assembly facilities

- Travelers at factory rollout: The number of unfinished jobs that travel from the final assembly

- Ticketing performance: The average number of escapes per ticketed airplane before delivery

The FAA evaluated the company’s supply chain shortages and employee proficiency, Whitaker replied, which he said are both trending in positive directions specifically in the 737 line and now in other lines as well, which will be used as the metrics for every aircraft model moving forward.

Boeing Strike

Currently more than 33,000 Boeing workers, represented by the IAM labor union, have been on strike since September 13 demanding higher wages and a reworked benefit package. In 2016 Boeing revoked its worker’s pensions and froze benefits that many employees had already accrued.

In January of 2014, union members approved ending its pension plan by September 2016 in favor of a new defined-contribution 401(k) plan. Just three months later, Boeing announced that it will be cancelling its pension for a new defined-contribution 401(k) plan for all nonunion employees starting January 2016 in an effort to improve cashflows and its long-term financial health.

Boeing announced a final offer to striking IAM workers Tuesday, September 24, which, if approved by union members, would increase the average annual machinist pay at the end of this 4-year contract would increase from $75,608 a year to $111,155.

Author: Kienan Briscoe