EVERETT—After a successful first cohort, Edmonds College’s Advanced Manufacturing Skills Center (AMSC) is currently enrolling students for its next Robotics and Manufacturing program which begins on January 26.

The program offers students a focused, career-oriented educational pathway where they learn how to maintain equipment, supervise production, or troubleshoot problems with automated systems, robots, and innovative machinery.

The first cohort of AMSC’s Robotics and Manufacturing program began in October, 2025, and spanned eight weeks (four weeks online, and four weeks in person) but the program is set to expand to a 12-week program in its next cohort in addition to transitioning to four-hour-a-day, part-time, classes instead of six-hours-a-day like before.

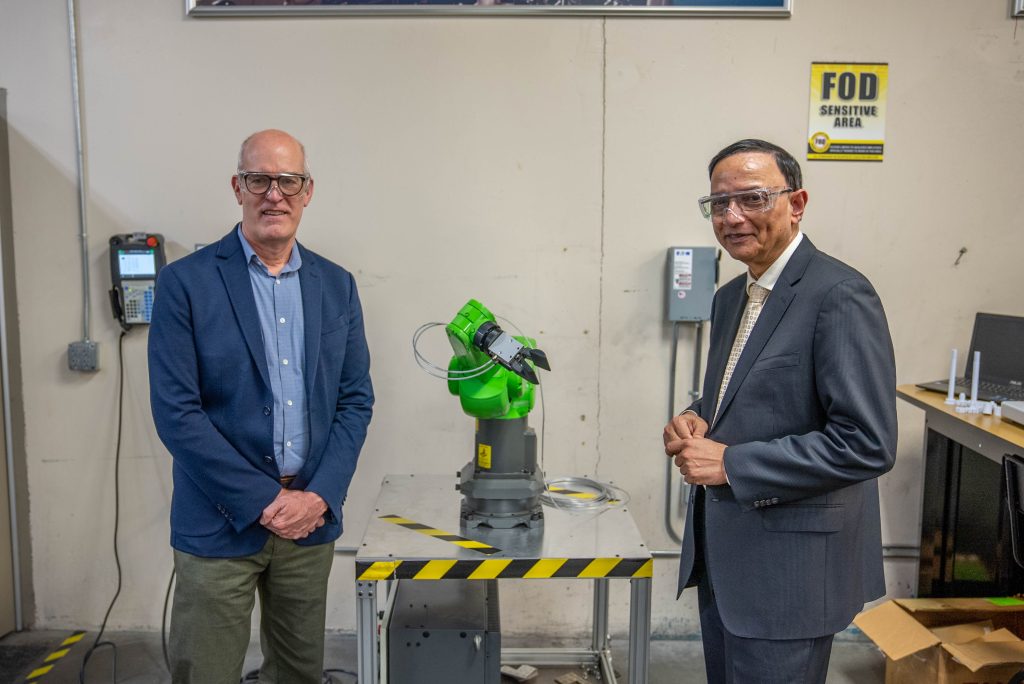

“What we’re trying to do is speak to a lot of different audiences, whether someone is coming in being interested in becoming a robotics technician, which is the entry level point, or someone who is already working in the industry – like Airbus or Boeing, where they’re starting to use a lot of robotics and automation in what they’re doing,” said Jim Werth, Marketing Manager for the AMSC.

Classes are intentionally capped at just six students per course to intentionally foster a more “hands-on” experience, Robotics and Manufacturing instructor Garrett Suryanto informed the Lynnwood Times.

“Every robot requires maintenance and service. There is some labor that is being replaced by AI and automated services – for example if you look at Amazon’s fulfillment center, they’re beginning to replace humans with robotics and conveyer belts. However, these robots still require a human to monitor it and perform maintenance,” said Suryanto. “That’s the goal of our students in this program, to get a job, to be a catch-all – putting together systems, troubleshooting systems, working electrical, and so on. With jobs in robotics, you can go anywhere – aerospace, medical, anywhere. ”

Suryanto’s course is designed to develop practical skills that increase students’ value in any manufacturing role — ranging from maintaining equipment and supervising production to troubleshooting automated systems, robots, and smart machinery. Absolutely no technical background required, Suryanto added.

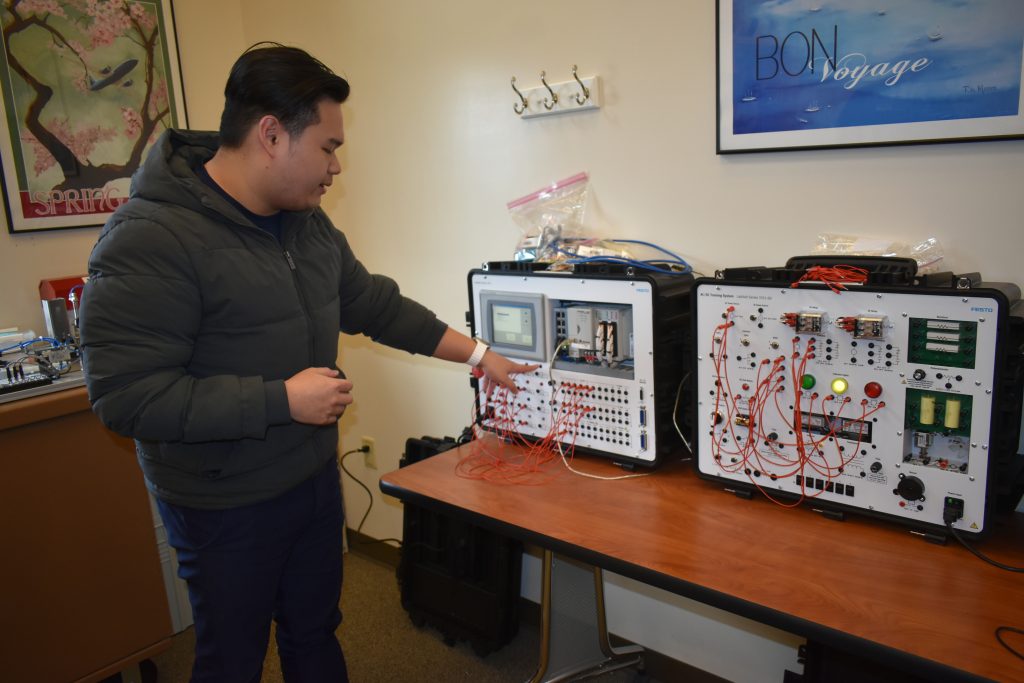

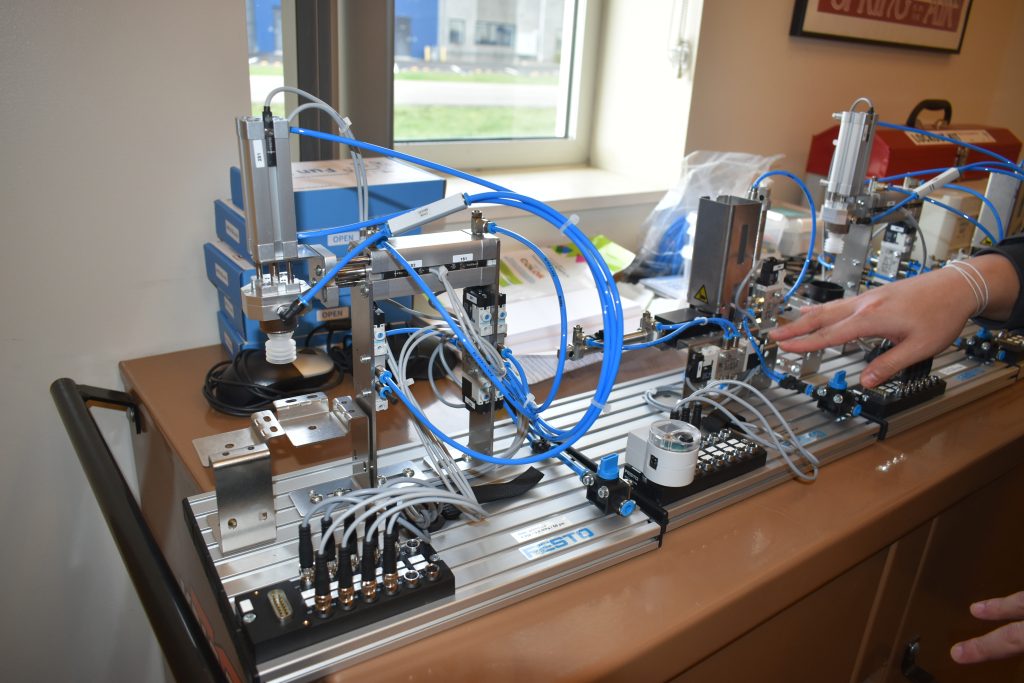

The initial four-week online module covers safety and basics to ensure students learn the ropes before even stepping foot into a classroom. Students then learn the basics of electrical, such as AC and DC power, capacitors, resisters, and so on. Third, students learn pneumatics which is the “powerhouse of robotics,” Suryanto said.

“Electrical is electrical – there’s no moving parts, but most robotics these days use pneumatics which is the air pressure that creates moving parts,” said Suryanto. “In our class we teach our students how to use an actuator, use schematics and diagrams, and make their own projects, and hold labs, to get hands-on experience.”

The last component to the Robotics course is simulations and PLC, which Suryanto described as the “brains” of a robot.

“Once you have the hands and feet – the pneumatics, the electrical – now you have to get something that controls it and tells it what to do and when. They will be hooked to these sensors, and the sensors will tell the pneumatics to move with the electrical,” said Suryanto.

If that sounds like a lot in one course: It is, added Jim Werth, because the very program was designed to “push your muscle memory to retain the information and be successful in the field.”

Still, the program was designed with accessibility in mind with just 8th grade level math and reading requirement (because you still need to read diagrams and blueprints, but also the idea of applied math and how to utilize it in systems).

What separates the AMSC robotics course from, say, a high school robotics club, for example, is that it’s career-focused with industrial purposes in mind.

“In high school robotics clubs they typically focus on robotics as a hobby, but necessarily a career. Our program is really the steppingstone for you to learn how robots are being used in industries,” said Suryanto. “Still, if a high school student has a background in robotics and wants to pursue a career as a technician, they will have a little bit of an advantage.”

AMSC partners with industry employers to identify, develop, and deliver the skills their employees need to remain competitive. Training pathways may include maintenance, avionics electronics, mechatronics, production line diagnostics, field electronics, electronic controls, metrology, and specialized electronic device repairs.

The Robotics Manufacturing course, though just launched last fall, has been a two-year-in-the-making idea beginning with a $1.3 million grant which Representative Rick Larsen helped secure. Half of this amount also went towards Edmonds College’s new Maritime program.

According to Werth, the AMSC can’t see itself expanding the program into a two-year program any time soon, but possibly in the future. As a program that’s been, essentially, “built from scratch,” Werth said, the goal for now is just to cement a program that works and build a network of industry leaders (such as SpaceX, Amazon, and Boeing) to invest in its longevity, in exchange for a qualified candidacy pool.

Why this matters, according to AMSC, is in today’s manufacturing world, automation is everywhere – from car assembly lines to food packaging, pharmaceutical production to electronics manufacturing. Modern factories use “mechatronic systems” – smart machines that combine mechanical parts, electrical systems, and computer controls to work together seamlessly.

Countless robotic mechanisms create the items, devices, and vehicles we use every day. The manufacturing industry requires extreme precision and repetitive tasks, making robots a natural choice for many projects. At the AMSC, students will acquire the skills to work with these robots and automated systems in simulated manufacturing environments.

“This new age in manufacturing is growing exponentially as more companies turn to robotics to increase efficiency, productivity, and safety on the shop floor. It’s estimated that half of all workers in robotics will need upskilling or reskilling to adapt to new or changing job roles in the next five years,” the college said.

Those interested in enrolling in AMSC’s Robotics and Manufacturing class can do so by visiting: https://amsc.edmonds.edu/programs/robotics/

Author: Kienan Briscoe