EVERETT—At the Construction Pre-Apprenticeship Program (CAP), Edmonds College students can undertake intensive training with hands-on experience, granting them an upper hand in the job market, at absolutely no cost to them.

The CAP is an eight-week, 300-hour tuition-free intensive program held at the Advanced Manufacturing Skills Center (AMSC) at Paine Field. CAP is intentionally designed to remove financial barriers, making high-quality training accessible to a diverse range of learners. Graduates leave the program with foundational knowledge, practical experience, and a clear pathway into well-paying careers.

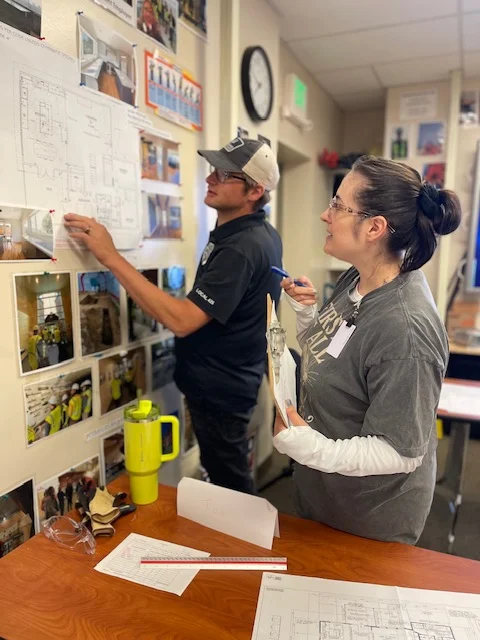

Students enrolled in Edmonds College’s CAP program learn electrical, plumbing, carpentry, iron work, knot tying, and basics from reading a tape measurer to safely operating power and hand tools at absolutely no cost to them, though other courses through the AMSC – such as the aerospace manufacturing program – still require payment.

By the end of the course students will be certified in operating a fork life and have OSHA-10 certifications, and flagging cards.

The class is intentionally capped at just 10 students at a time to get the most out of hands-on instruction. There is currently a waitlist of approximately 25 students in queue, according to the college.

Through the CAP program’s duration, students will have the opportunity to tour approximately eight (about one a week) local unions to learn, firsthand, how to pave cement, lay pipes, or tour construction sites.

Upon completion, Students are also gifted “care packages” consisting of starter tools, boots, hard hats, and other resources that are often required prior to beginning a job in a chosen field. These care packages are made possible through Cares of Washington as well as certain construction companies.

Through a partnership with Cares of Washington students can even be eligible to receive free gas cards (to get them to-and-from work/class), work clothes, and boots.

The CAP program is instructed by union carpenter and Lynnwood resident Bryce Owings.

“This is a great program. We need to make sure we keep this funded to ensure all people can come in here because no matter what your background is financially you’re able to get some real skills here, where if it was charged from their [the student’s] pocket it would really cut off a lot of people who couldn’t afford it,” said Owings. “These are the kinds of skills that are needed in the future, in my opinion, because with the rise in A.I you’re not going to see many of these tech jobs that everyone’s going for. But A.I. is never going to replace someone with a hammer or an electrician running wire.”

Edmonds College’s CAP program started in 2021, when Sound Transit partnered with the City of Lynnwood and Edmonds College to begin a pre-apprenticeship program. At that time the transportation authority was having a hard time building up its workforce for the incoming, extremely ambitious, light rail project. One of the board members, who also sat on the Board for Edmonds College, approached then Mayor of Lynnwood Nicola Smith with a solution; a solution which eventually became the Construction Pre-Apprenticeship Program (CAP).

It quickly became evident, however, that the capacity of the program could not be effectively operated on Edmonds College’s main campus in Lynnwood. Instead, it was set up due north at the Washington Aerospace Training and Research Center (WATR) in Everett, which opened in 2010 as an educational resource for career pathways in the aerospace and manufacturing industry through an operating agreement with the Aerospace Futures Alliance (AFA).

The WATR center is also located near Paine Field Airport for a very specific reason – a requirement beset by Boeing, one of WATR’s primary partners, who, during initial conversations with the college in 2009, was in dire need of assembly workers with “skills, not degrees,” Sheila Dersham, Associate Director for the WATR, told the Lynnwood Times.

“The movement away from skills-based training has caused us to have a huge deficit in people who actually do jobs that require skilled labor,” said Dersham. “There’s only so many jobs for people with degrees and we’ve neglected the trades for a while, but I think that’s on the upswing.”

Both the CAP program and the college’s 12-week Aerospace manufacturing program fall within its AMSC which used to be a Business Training Center until being converted to cover more divisions of the manufacturing sector.

Since its inception, the CAP program has had 112 students enrolled (since October of 2021) with 106 of them graduating – a 93% completion rate. Of these students, 50% were members of the BIPOC community and 17% were women, both underrepresented demographics in the trades. Additionally, nearly 23% of graduates exited the program with apprenticeships (at least in union-based jobs, non-union based career opportunities are harder to track via data).

“Our graduates are preferred. They have a leg up, so to speak. If there is an interview process and people are coming from everywhere, and graduates from the pre-apprenticeship program, unless something goes wrong, they are on the top of the list,” said AMSC Executive Director Matt Poishbeg.

On average, graduates of the CAP program make $5 more an hour compared to prior to completing the program.

Cindy Fisher, Student Services Coordinator with the AMSC, works in constant communication with the region’s largest trade employers for job opportunities and works closely with graduating students to help them develop key skills beyond the trades (such as resume building, interviewing skills, and so on.) She keeps in contact with graduates long after their eight weeks to put them in touch with job opportunities or help them build their resumes.

“One of the biggest things for us is making sure they [the students] have the skills for, not only interviewing, but doing math and agility tests,” said Fisher. “What we try to do is hit a little bit on every trade so that they’ll be high on the list of candidates.”

When a student of the CAP program first enrolls, Fisher interviews them to figure out what trade they’re most interested in entering. She then actively works with them on goal setting, coordinates mock interviews with unions such as L&I, and connects them to additional certification programs such as electrical certifications offered by the Construction Industry Training Center (CITC).

The CAP program is currently a non-credit program though the college is looking into changing that soon. While other programs offered through the AMSC are eligible for college credits they are all non-tuition funded, which creates a unique funding model. For one, it does not have FTE (full time enrollment) requirements to receive funding (like most college programs) but that also means it does not receive state funding, leaving it almost completely reliant on grants.

Despite this, the AMSC has been historically successful in securing grants (such as the recently awarded $300,000 grant from Jobs for the Future and an additional $500,000 grant from WSDOT to support its CAP program). Because of these successes, not only is the AMSC not worried about recent state and federal dollar restrictions to keep afloat, but it has its heart set on expansion soon offering even more trade field training in a (hopefully, if all goes according to plan) brand new building.

“I’m not too worried about our programs because we promote employment. We’re getting people jobs and we’re giving opportunities to people who have a hard time getting jobs. I think in the grand scheme of things I think we’re probably going to come out okay,” said Associate Director Sheila Dersham. “Even if there are not as many state or federal opportunities we look for other options and we work with other organizations that have the same goal – working with people who don’t always have the opportunity to go to school.”

According to AMSC Executive Director Matt Poischbeg, the hope – as it relates to expansion – is to one day have a designated CAP space where students can create sawdust, for example, without contaminating other spaces.

Poischbeg continued that he would also like to one day get to a point where the AMSC can buy students the necessary tools and equipment needed to start a job day one.

“It’s what we call wraparound services. Where you’re not just offering the program, they come in, and it’s a passive thing. We want to give them the support they need,” added Dersham.

Students interested in learning more about the CAP program can attend a tour and open house on Wednesdays.

Author: Kienan Briscoe

One Response

GREAT