MARYSVILLE—Startup companies are far from a foreign concept for the Seattle metro area but startups that manufacture space stations are few and far between. Gravitics, a Marysville-based startup manufacturing the next generation of spacecraft, hopes to forever change the landscape of orbital space travel by significantly cutting costs while offering more livable space for off-planet travel.

Mike DeRosa, Co-Founder and CMO at Gravitics, made an appearance at Economic Alliance Snohomish County’s annual meeting at Tulalip Resort and Casino posing an important question: What would happen if our earth was just a little bit larger?

DeRosa commented that the earliest form of the human species is known to exist about 2 million years ago but spaceflight, and flight at large, has only existed for a small sliver of that history—the Wright brothers creating the first successful powered airplane in 1903, and successful space missions only entering the picture in the 1960’s.

Orbital spaceflight, which differs from suborbital spaceflight in that it circles the earth at least once, stably, and achieves an orbital velocity of at least 17,500 miles per hour of speed. To put this into perspective, commercial airplanes go approximately 400 to 500 knots, which is about 460 to 575 miles per hour when traveling at an elevation of 36,000 feet. This is the fastest thing we do other than space travel.

Beginning from zero, going sideways that fast, obviously requires an extraordinary amount of energy, or a rocket that’s basically all fuel. All modern rockets that go into space separate into stages with only the tip of the rocket housing staying in space. This is done because the more mass an object has, the more energy it takes to move (Force = mass x acceleration and Work = Force x distance).

In space travel, the rocket is discarded after a single use with the engines alone costing millions of dollars. If air flight was the same way, it would be way too expensive for any airliner to do. For example, when an airplane lands safely, its passengers deboard and the next group boards the same aircraft without the airliner requiring a new fuselage or set of engines.

Going back to DeRosa’s original question: even if the earth were 5% more massive, or a super earth, it would be more than 5% harder to get to space as the laws of physics are not linear—Escape velocity is equal to the square root of 2 x Gravitational constant x Mass of the Earth all divided by the radius from the center of the Mass. It would require more fuel to overcome the new escape velocity requirements of a bigger earth, because gravity would be stronger, for one. It would then require even more fuel to maintain the necessary velocity to remain in orbit.

We are ready for next-gen launch vehicles. Are you?

Starship's performance in space today is only the beginning. Congratulations to SpaceX, NASA, and every person working on the Starship program. pic.twitter.com/KyFDVxqiiq

— Gravitics (@GraviticsInc) March 14, 2024

Launch companies are just beginning to revolutionize how to reuse components in space travel, and trending in the direction of being more efficient like in the aviation industry. There have already been dramatic reductions in cost in recent years but companies like SpaceX are working hard to cut these costs further. Blue Origin, located in Kent, Washington, is also working on a reusable spacecraft.

Gravitics is unique in the industry, in that it’s a “space station startup,” which you don’t really hear all that often about startup companies. For there to be a space station startup, on the other hand, there needs to be a thriving space station industry.

As of 2023 there are two active space stations in orbit, China’s Tiangong Space Station where two people are currently living in orbit, and the I.S.S. (International Space Station)—a collaborate effort by five space agencies representing 15 countries—where six people live at a time. These space stations are manufactured by the companies who operate them but there has been no company that manufactures space stations for sale…until Gravitics.

“We’re not here to be space station operators in the near term. We looked at the business landscape and saw there is no company that’s building the next generation of space stations for sale right now – so that’s what we’re doing and we’re doing it right here in Snohomish County” said DeRosa.

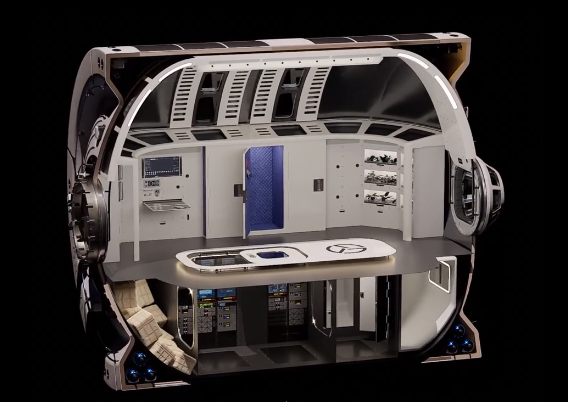

Gravitics modules offer endless possibilities in space with up to 400 cubic meters of usable volume—almost half of the ISS. [thread] pic.twitter.com/rxvpwm3SVK

— Gravitics (@GraviticsInc) October 4, 2023

Gravitics operates out of a 42,000 square-foot facility in Marysville with up to 50 employees, with hopes of growing to the hundreds in the next couple of years.

The company looked at several places when deciding where to open shop—Florida, Texas, California, where many space startups begin—but ultimately decided on Marysville for its proximity to water (for shipping purposes), its ecosystem, and workforce.

“If you can build an aircraft for Boeing, you can build a spacecraft for us,” said DeRosa.

Gravitics products include its flagship 4, 6, and 8-meter module StarMax, named because it maxes out the starship class experience. Most space stations currently use 4-meter modules so the 6 and 8-meter are quite the step-up in terms of space. On Gravitics’ website it states, “humans need large living spaces” and the company lives by this with its 400-meter cube of real estate with each StarMax product.

The StarMax has flexible configuration and can be customized per order. Its diameter is 7.6 meters (25 feet) and height of 9.8 meters (32 feet) provides 400 meters cube of internal volume. The company also claims it’s the most robust, safest hull ever to launch with external and internal mounting options.

The startup also has its own software team which is moving into flight software, navigation and control, and propulsion.

DeRosa said you can imagine Gravitics’ products like a large metal balloon floating up in space because it traps the air in while also shields from radiation (MMOD shielding), has solar cells affixed to the outside to manage energy coming from the sun (at a rate of 8 kilowatts of electricity), and manages kinetic energy from any impacts.

“We’re really excited for the future of when you can get bigger and bigger things into space,” said DeRosa.

The use for the type of product Gravitics builds goes beyond commercial space travel. It could be used for cargo delivery, cargo storage, orbital compute, space tourism, space stations, pharmaceutical production (3D printing organs, for example, which would fall apart on earth due to the weight of gravity), and even manufacturing—being able to offer a zero-gravity environment for manufacturing purposes.

DeRosa speculates that within the next 10 years space tourism will be as accessible for people as a family trip to Disneyland in terms of cost.

“We are aspiring to look at production in the space industry differently than has been traditionally. Traditionally, you build one spacecraft, maybe two…maybe a backup, maybe a pathfinder for it. What we’re building is the tooling to be able to repeat it. We’re hiring more and more manufacturing people, we already have a few, who are going to be able to crank these out,” said DeRosa adding that the company wants the manufacturing so simple that a “high schooler could press a button on the assembly line.”

Gravitics raised $20 million in 2021 and has already spent at least $10 million of that in Snohomish County. The startup only has one challenge; it needs more power in its facilities so it’s looking at upgrading its breaker boxes.

The company also recently signed a contract with the United States Department of Defense which has an undisclosed use for the StarMax and its other products.

RELATED ARTICLE